The Term Used to Describe the Continuous Improvement of Processes Within a Facility is Quizlet

What Is Continuous Improvement?

Continuous improvement is a company culture that encourages all employees to look for ways to enhance the business's operations. This includes suggesting ideas to improve efficiencies, evaluating current processes, and finding opportunities to cut unproductive work.

The modern business concept of continuous improvement dates back to Toyota's innovative manufacturing processes. The company used the term kaizen, which means "change for the better." Toyota wanted to focus its employees' attention on a single goal: look for ways to improve the business.

Is Continuous Improvement the Same as Continuous Delivery?

No, although these two models are related. Continuous delivery is a narrow concept. It refers to a software company's ability to publish updates to its products quickly. To become successful at continuous delivery, a product team must adopt agile practices. Here are a few common examples:

- Breaking work into small batches

- Holding everyone accountable

- Sharing responsibility across the team

- Defining processes to push code live at a moment's notice

Continuous improvement is a much broader concept. It describes a strategy focused on improving processes, increasing quality, and cutting waste. Experts believe that to achieve continuous delivery, a business should apply the continuous improvement mindset.

What Does Continuous Improvement Look Like?

The day-to-day practices of a company using continuous improvement can vary widely. But there are several common traits you will find among businesses that use this approach.

Everyone can contribute ideas.

Great ideas can come from anywhere in a company. But without a process to get ideas to the right people, the business will miss out on those improvements.

A company using continuous improvement correctly will create a culture that welcomes and rewards suggestions from any employee who can improve some aspect of the business.

Employees are encouraged to call attention to problems, even small ones.

When they introduced the kaizen concept at Toyota, that team understood that small process inefficiencies could lead to big problems over time. The company encouraged its employees to raise their hand when they encountered an inefficiency in any area of operations. This could include an unnecessary step in a process or a technology that could be improved.

The idea works just as well today, for any business. If an employee can find a faster or more cost-effective way to complete a task, and if employees are always on the lookout for such improvements, this can lead to significant improvements over time.

The team regularly reviews its progress.

For continuous improvement to succeed, the company needs to step back and evaluate its new processes or changes to old ones. (Without these reviews, the company will know only that it is engaging in continuous changes, but not necessarily an improvement.)

In an agile company, a retrospective is one example of this type of review. A retrospective is a meeting held after the product team ships a product to the market. The goal is to review what processes worked during the product rollout and which need improving.

The company welcomes updates to processes (even longstanding ones).

Businesses build processes and routines over time. Some might no longer be the most efficient ways of working, even if they were when the company implemented them. Unless the organization re-examines its methods, it might not realize if its teams are no longer working in the most efficient ways.

A company applying the continuous improvement strategy will welcome these discoveries. They will also gladly change or eliminate processes that no longer serve the company's interests.

One example could be a product development team moving from a complicated task management approach to a more streamlined Kanban, as shown below.

Using this Kanban-style roadmap in ProductPlan's roadmap software, a development team can achieve several strategic benefits:

- Give stakeholders an at-a-glance view of which projects are underway, which are done, and which are next in the queue.

- Easily adjust the amount of work in progress (WIP) to the team's capacity.

- Give the team a clear view of its progress and the work outstanding to pace itself properly.

What Does Continuous Improvement Mean for Product Managers?

Continuous improvement refers to a companywide effort to enhance operations across the business. But product managers can use this strategy to improve both their team's processes and the products they build.

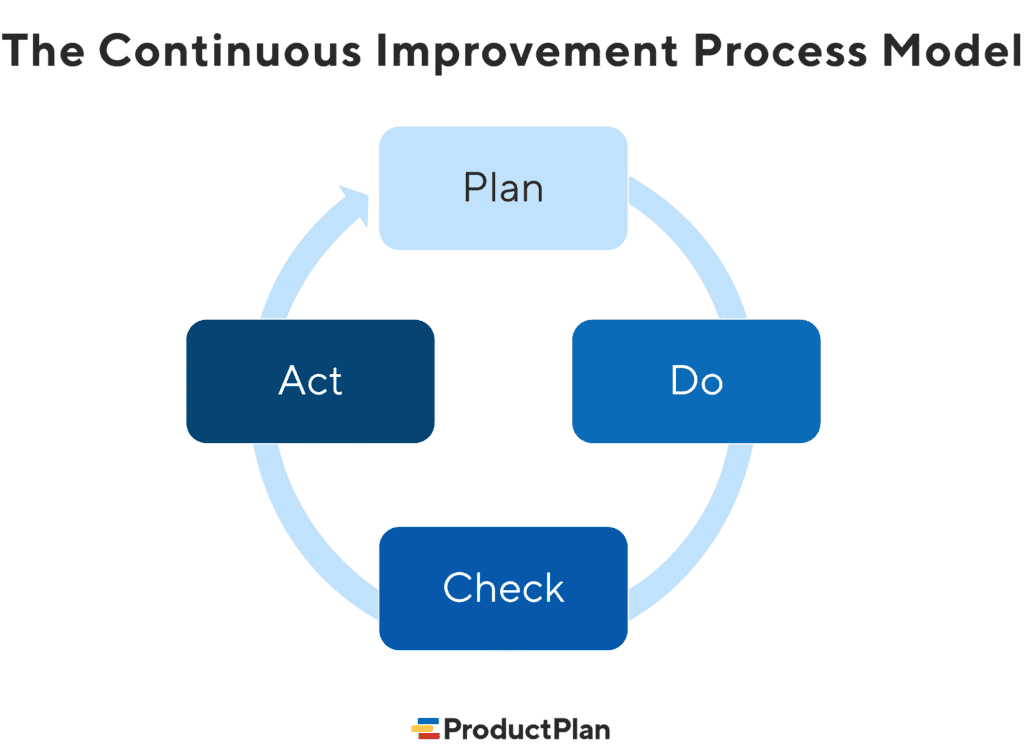

The most popular continuous improvement method is a four-step framework called PDCA: Plan, Do, Check, Act.

Imagine a product team looking for an agile process to iterate on their products regularly. Here is how they can use this approach to introduce incremental improvements and learn whether they resonate with users.

Plan

This is the stage where the product managers will research the market, analyze data, and develop an idea for an improvement to their product. You can also think of this as the hypothesis stage.

When they have their hypothesis—let's say an idea for a new feature—the product managers will develop a plan to build it. The plan will include making sure the team has the budget, time, and resources to execute.

Do

The Do stage is when the product team takes action. In the case of a new product feature, this means working with the development team to build a working version of the feature ready for testing and user feedback.

Check

This is the test phase. With a working version of the feature, the team now puts it into users' hands, monitors their usage, and encourages their feedback.

If users have criticisms of the new functionality, the team will need to reevaluate its plan and hypothesis. If the feature receives positive reviews from users, the team can move on to the final stage of this cycle….

Act

The team will now make needed adjustments to the new feature, build it into the product, and push it to customers.

Finally, the team will start the cycle over. They'll return to the first phase—Plan—and begin looking for new functionality their market might need.

Related Terms:

lean software development, continuous delivery, Scrum agile framework, Kanban board, enterprise transformation

Source: https://www.productplan.com/glossary/continuous-improvement/

0 Response to "The Term Used to Describe the Continuous Improvement of Processes Within a Facility is Quizlet"

Post a Comment